The archaeological section at the Norwegian Maritime Museum has been using FARO arms for the documentation of archaeological boat and ship remains since 2007. A FARO arm is a type of coordinate measuring machine (CMM). For the sake of simplicity, it can be described as an advanced digital pen that makes it possible to measure and record an object in three dimensions with high precision. The FARO arm is connected to a computer running Rhino3D, a computer aided design (CAD) program. These tools help rationalise any later reconstructions of the finds, whether as physical or digital models.

The documentation lab is where all waterlogged archaeological boat and ship remains are received when they come in from an excavation. The remains are cleaned and stored in large, water-filled tanks to prevent drying while waiting to be recorded. Each boat or ship timber is recorded using the FARO arm. As most of the vessels that are delivered to the documentation lab have been split into their individual parts during excavation, good field documentation is essential to establishing the placement and orientation of each timber during recording.

- 1/2

Archaeologist from the documentation lab cleaning boat parts. Norsk Maritimt Museum/Tori Falck - 2/2

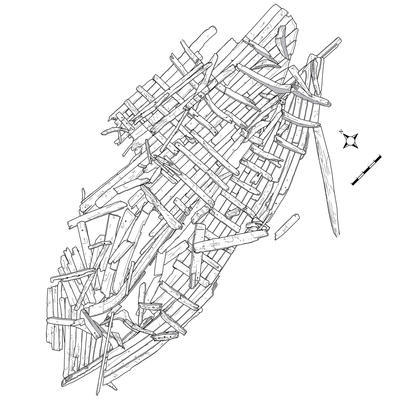

Good field documentation, like this site plan, is essential to the later documentation work. Norsk Maritimt Museum/Rune Borvik

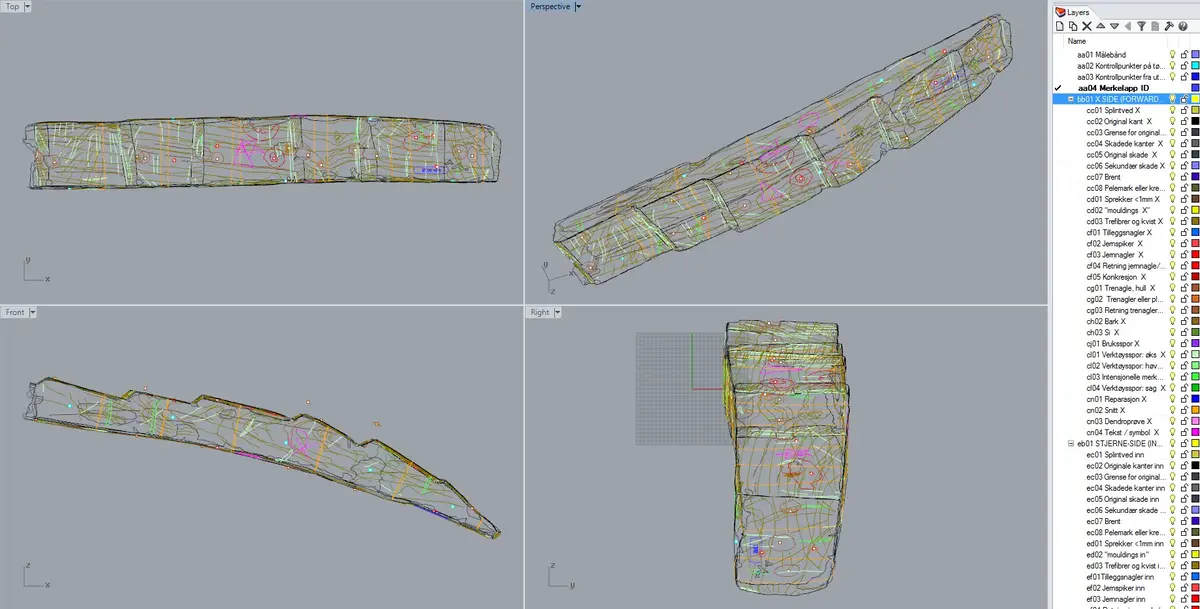

Planks are recorded as two-sided 3D drawings, while frames, knees, beams, keel, stem- and stern parts are recorded as four-sided 3D drawings. To ensure that all necessary information is included in the drawing, a recording template developed at the Viking Ship Museum in Roskilde, later refined at the Newport ship project, is used. The outer edges and fasteners on each timber are particularly important to any later reconstruction work. Amongst other features recorded are tool marks, timber conversion, the placement of waterproofing materials and damages.

- 1/1

Rhino3D drawing of a partial floor timber. The layer menu doubles as a checklist for the recording archeologist. Norsk Maritimt Museum

Upon completion of recording, a detailed report on the recorded parts is written, also focusing on construction techniques, choice of materials, signs of repairs, etc. In some cases a scale model, usually 1:10, is built by the recording archaeologists. Two-sided model parts can be made by flattening the scaled down 3D drawings and printing them on paper. The printouts are then glued onto cardboard of the desired thickness and cut to shape. In some cases it can be useful to 3D print two-sided parts, although this is normally only done for the four-sided parts. When a physical model is completed, it is measured with the FARO arm, and a digital model can be created based on these measurements. This can then be run through hydrostatic analysis software, which tells us the vessel's cargo capacity and stability. The museum currently uses the Orca3D plugin for Rhino3D for these analyses.

Since 2007, the documentation lab has recorded 38 archaeological boat finds of varying size and preservation state with FARO arms. Eight of these have been made into models; Barcode 1, 2, 5, 6, 8 and 14, Sørenga 7 and Vaterland 1. A full scale reconstruction of Barcode 6 has been built in the museum's Boat Lab, where the next full scale reconstruction project, Vaterland 1, started in 2017. Below is an edited digital version of the Vaterland 1 model as it was built in the documentation lab. The full scale reconstruction is based on a second, more recent model of the Vaterland 1 find.

In addition to FARO arms, the lab also has photography facilites. Some objects are less suited for FARO arm recording, in which case they can documented using photographs and photogrammetry. The model shown below, which is part of a bilge pump from an archaeological ship find, was made using photogrammetry.

Tori Falck